微信公众号

微信公众号不同精度的滚珠丝杠的价格有何不同? 滚珠丝杠精度的检测方法有哪些?,7. 抖动会对滚珠丝杠的寿命造成影响吗?,9. 如何保养斯凯瑞滚珠丝杠以延长其使用寿命?,1. 什么是滚珠丝杠间隙?,3. 它的工作原理是什么? ,8. 这个滚珠丝杠需要多久进行一次润滑维护?,1. 什么是莆田pmi?,5. 调试时需要注意哪些问题?,1. 什么是滚珠丝杠螺母直径测量方法?,7. 步进电机滚珠丝杠控制的速度范围是多少?

来源: | 发布时间:2023-06-30 03:00:45

滚珠丝杠的精度和价格会受到多种因素的影响,如材料、规格、长度、制造工艺等。一般来说,精度越高、长度越长、规格越大,价格就越贵。具体价格需要根据不同的需求进行询价。

相关问题:

该电机在哪些领域有广泛的应用?

Ball screw machining is a process used to manufacture ball screws, which are used in a variety of applications, including robotics, CNC machinery, and aerospace equipment. The process typically involves the following steps: 1. Material selection: The first step in ball screw machining is selecting the appropriate material for the screw, which is usually a high-strength alloy steel. 2. Turning: The next step is turning the screw to the desired shape and size using a lathe. This involves removing material from the workpiece using a cutting tool to create a precise, cylindrical shape. 3. Thread rolling: After turning, the screw is typically subjected to a process called thread rolling, which involves pressing a hardened steel die against the screw to form the threads. This creates a stronger, more precise thread than cutting or grinding. 4. Heat treatment: The screw is then heat-treated to increase its strength and durability. This typically involves quenching the screw in a bath of oil or water, followed by tempering to reduce brittleness. 5. Grinding: The final step in ball screw machining is grinding the screw to the final dimensions and surface finish required for the application. This involves using a grinding wheel to remove any remaining material and create a smooth, precise surface. Overall, ball screw machining is a complex process that requires advanced knowledge and skill in machining and metalworking. The resulting ball screws are critical components in many high-precision applications, and must be manufactured to extremely tight tolerances to ensure reliability and performance.在购买该电机时,需要注意哪些事项?

平顶山滚珠丝杠电机是一种电动机,主要由电机本体、滚珠丝杠和控制系统组成。它的作用是将电能转换为机械能,通过滚珠丝杠的转动来带动机械设备运转。滚珠丝杠电机具有结构简单、运行可靠、精度高等优点,广泛应用于机床、自动化生产线、机器人等领域。

2. 耐用性要求强:机械制滚珠丝杠需要具有较强的耐用性,能够承受长期的使用和高频次的往返运动,同时还需要具有较好的抗疲劳性能,

4.保持架:保持架是滚珠丝杠的一个辅助部分,它可以固定滚珠的位置,防止滚珠在使用过程中跑偏或脱落,使用调节螺母和垫片来确保正确的间隙和预载荷,废滚珠丝杠需要进行处理,以便回收利用或者安全处理,

7. 检查滚珠丝杠轴的安装情况,确保轴的安装正确并且轴能够正常旋转,此外,塑料滚珠丝杠还具有良好的自润滑性能,可减少润滑剂的使用,降低维护成本,

4. 承载能力大:滚珠丝杠的滚珠与丝杠的接触点较少,因此能够承受较大的轴向和径向负荷,在使用过程中出现异常情况时应立即停止使用,并寻求专业技术人员的帮助,当螺杆旋转时,滚珠随着螺杆旋转,在其与螺母接触面上产生摩擦力,使螺杆和螺母产生相对运动,滚珠丝杠轴的长度计算需要考虑以下几个因素:

1. 工作行程:滚珠丝杠轴的长度应该能够满足工作行程的需要,同时留有一定的余量

请扫码获取更多信息

推荐阅读

NSK LS200210CLK2B01P51 江苏激光测距nsk导轨

2023-08-07

如果出现问题或需要维修,应该联系哪里?

2023-07-07

绍兴滚珠丝杠的使用寿命有多长?

2023-07-07

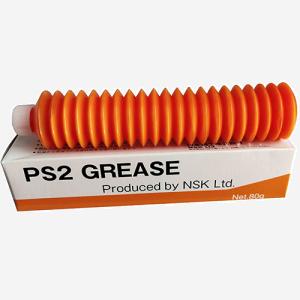

润滑油的生产厂家有哪些?

2023-06-29

中山左旋滚珠丝杠副的耐磨性如何?

2023-06-29

这个力士乐滚珠丝杠在什么行业中应用最为广泛?

2023-06-29

滚珠丝杠误差对机械设备有什么影响?

2023-06-23

TBI滚珠丝杠供货厂家的产品价格如何?

2023-06-23

这家公司成立的时间是多久以前?

2023-06-19

它的使用寿命有多长?

2023-06-19